Abstract

Objective: The purpose of this systematic literature review was to evaluate the impact of different surface treatments applied to zirconia on the bond strength between cosmetic ceramic and zirconia.

Material and methods: A systematic literature review was carried out using electronic databases PubMed and Science direct. Studies meeting the following criteria were included: studies comparing the bond strength between Y-TZP zirconia and cosmetic ceramics after different surface treatments, measured by the SBS test, studies published after 2010, with sample sizes greater than or equal to 30. The identification and selection were based on the Critical Skills Appraisal Programme (CASP). This systematic review followed the guidelines of PRISMA Statement (Preferred Reporting Items for Systematic Reviews and Meta-Analyzes).

Results: Among the 277 references initially found, 25 articles were selected. Different surface treatments were studied: physical, chemical, and physicochemical treatments. The majority of surface treatments applied to zirconia increased the bonding value between zirconia and the cosmetic ceramic. Variations in samples, treatment protocols and shear bond strength (SBS) test protocols contributed to the heterogeneity of the results.

Conclusion: Further in vitro studies with standardized protocols and clinical studies taking into consideration occlusal forces, arch area, number of abutments and restoration design are required.

Key words

zirconi, cosmetic ceramics, shear bond strength, surface treatment- prosthodontics

Introduction

The use of ceramic restorations has grown considerably due to increased demand for aesthetic and technological advances [1]. Yttrium-reinforced polycrystalline tetragonal zirconia (Y-TZP) has become increasingly used as a ceramic restorative material due to its mechanical properties, as well as its biocompatibility, chemical and structural stability and optical properties [2-4]. Zirconia is used not only as a framework (on which an appropriate cosmetic ceramic is mounted by layering or by the press technique) but also for monolithic restorations (Monobloc zirconium coating or full contour) [4,5]. However, for aesthetic reasons, the first type of prosthesis (porcelain coating on a zirconium infrastructure) is preferred [5-7].

Several studies have evaluated the performance of zirconia-based restorations and reported a very high success rate of over 97.8% over a 5-year period [8,9]. However, delamination and fracture have been reported by the majority of studies as the most common complications of zirconia restorations covered with veneering ceramic. Sailer and all in 2009 reported that the failure rate of cosmetic ceramics was 25% in a randomized controlled trail with a follow-up of 3 years [10]. Therefore, zirconia surface treatment techniques have been developed with the aim to increase the bond strength between cosmetic ceramic and zirconia [11].

The objective of our study was to assess the impact of various surface treatments applied to zirconia on the bond value between cosmetic ceramic and zirconia through the shear bond strength (SBS).

Materials and methods

A literature computerized search was conducted in Pub Med and science direct, using 14 key words:

Mech terms used: Zirconia -Y-TZP-Zirconium oxide-Zirconium dioxide-Veneering porcelain-Surface treatment-Laser Nd:YAG- Laser CO2-Sol gel-Bonding strength- Polishing treatments Plasma treatment-Fluorhydric acid-Airborne particle abrasion

We selected articles that met the following inclusion criteria:

Articles studying and comparing the bond strength between Y-TZP zirconia and cosmetic ceramics, measured by the SBS test

In vitro studies randomized controlled trials, prospective studies, retrospective studies.

Papers published articles after 2010

Articles with sample sizes greater than or equal to 30.

In order to detect other articles, a manual investigation was done using a bottom-up research, based on the references previously identified.

A first reading was done to select the articles through the title and the abstract. Then, a second reading of complete content of the selected articles was carried out, eliminating articles that did not meet the inclusion criteria.

The quality of the included studies was assessed using the Critical Skills Appraisal Programme (CASP). Eligible studies received a "no" score for criteria 5, 6 and 10. These three negative responses resulted in a total score of 9 for the 25 studies. Data extraction and quality assessment of the publications was completed by 2 independent readers, with formal processes for discussion and consensus building in case of disagreement.

Results

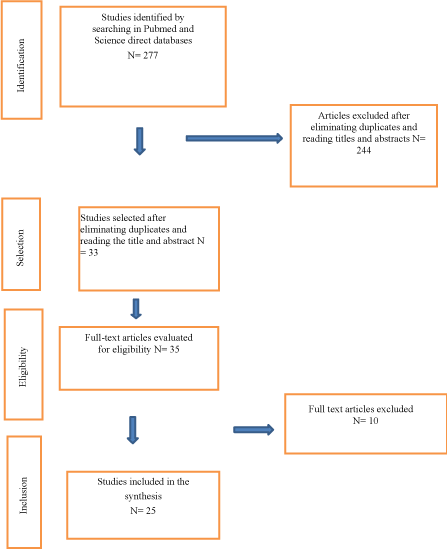

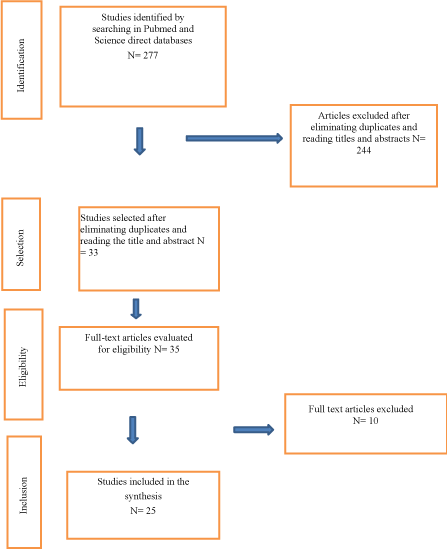

The search identified initially 277 studies, from which 33 articles were selected based on the contents of the titles and abstracts. Through manual search, 2 articles were founded. From the 35 articles, we eliminated 10 articles that did not meet inclusion criteria after reading the full text (Figure 1). The 25 references selected were in vitro studies and have created a total of 1902 samples.

Figure 1. Flow diagram illustrating the study selection process

he size of the samples ranged from 30 to 196 and their shapes varied from disks, cylinders, and cubes. Different brands of Y-TZP zirconia and cosmetic ceramics were used to make the samples. Only the study by Kirmali and all did not provide information in relation to the type of cosmetic ceramic used [12].

Regarding the technique of specimen fabrication, in 6 studies, block fabrication was performed via Computer Assisted Design / Computer Assisted Manufacturing (CAD/CAM) systems [5,13-17]. High-precision machines were used on pre-sintered blocks in 7 studies [4,14,18-22], and on dense blocks in 2 studies [17,23]. Henriques, et al. used pressure of zirconia powder in a mold [7]. In contrast, other studies did not describe the technique of block fabrication. [2-4,6,12,16,24,25].

In most studies, the ceramic was condensed on zirconia in two firings [2,3,5,6,12-14,16-29]. In others studies, the ceramic was mounted by the pressure/injection technique [6,7,9]. Only one study used the CAD-on technique, which is a new method combining the advantages of cosmetic ceramic/zirconia bonding and computer-aided design (CAD/CAM) [4].

In the last technique, both the Y-TZP zirconia and the cosmetic ceramic were milled using CAD/CAM technology. The two milled components were then bonded to each other using a glass-fused ceramic.

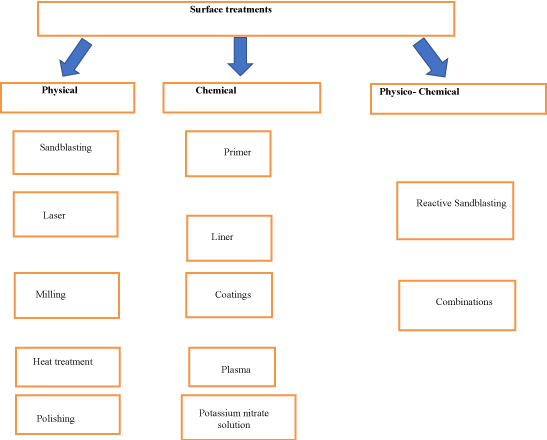

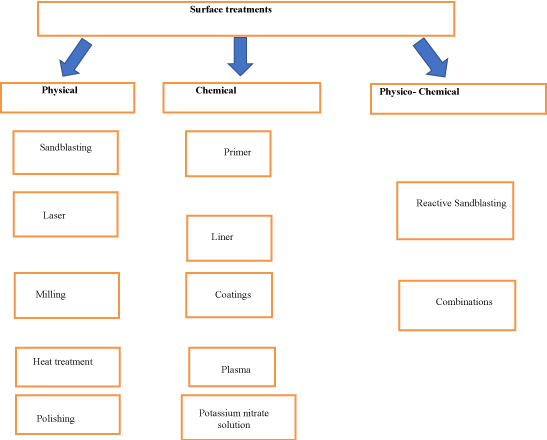

Various surface treatments were used in the 25 studies and are shown in Figure 2.

Figure 2. The different surface treatments studied

Sandblasting: Sandblasting, or the abrasion of airborne particles, was the most documented technique. 13 articles studied this type of treatment. A wide variation was found in particles size, pressure, duration, and blasting distance. The most commonly used aluminum oxide particle sizes were 50µm and 110µm. The SBS test values varied from study to study (Table 1).

Table 1. SBS test values after sandblasting

Authors |

Particle size (µm) |

Pressure (MPa) |

Duration

(Seconde) |

Distance (mm) |

SBS (MPa) |

Abdullah, et al. [26] |

50 |

0,25 |

10 |

15 |

From 27,27 ± 2,09

to 27,9 ± 2,73 |

Bitencourt, et al. [27] |

27-110-250 |

0,4 |

20 |

10 |

From 8,65 ± 3,71 to 13,67 ± 2,56 |

Kim, et al. [32] |

50 |

0,2 |

10 |

10 |

18,9 ± 2,9 |

JI, et al. [13] |

110 |

4 |

15 |

10 |

17,05 ± 1,36 |

Yilmaz,et al. [4] |

50 |

0,3 |

10 |

10 |

33,03 ± 5,05 |

Kirmali,et al. [12] |

120 |

0,2 |

15 |

10 |

15,98 ± 3,98 |

Korkmaz,et al. [17] |

120 |

0,35 |

10 |

10 |

11,64 ± 3,6 |

Nishigori,et al. [28] |

50 |

0,4 |

10 |

10 |

From 10,7 ± 15,4 to 34,1 ± 10 |

He,et al. [21] |

149 |

0,2

0,4 |

_ |

10 |

From 25,04 ± 4,78 to 35,02 ± 3,18 |

Liu,et al. [22] |

50 |

0,35 |

15 |

10 |

From 28,3 ± 5,1 to 31,3 ± 5,7 |

Teng,et al. [24] |

110 |

0,3 |

10 |

10 |

39,4 ± 6,5 |

Kim,et al. [23] |

110 |

0,4 |

10 |

10 |

36,63 ± 2,96 |

Mosharraf,et al. [6] |

110 |

0,35 |

5 |

15 |

From 26, 31 ± 2,53 to 28,51 ± 2,21 |

Laser treatment: Five types of laser were used. Table 2 shows the SBS values found in the studies included.

Plasma treatment: Four types of plasma treatments were presented in the studies included in our review.

Plasma enhanced chemical vapor deposition (PEVCD) film or plasma assisted chemical vapor deposition: bonding values that ranged from 14.73 ± 3.04 to 15.99 ± 2.62 MPa were found in the study of Bitencourt, et al. [27].

Argon plasma was studied in four studies and the bonding values ranged from 16.37± 1.60 to 33.9 MPa [13,18,16,29]

Oxygen plasma: The study by Liu, et al. in 2018 gave bonding values that ranged from 12.62 ± 2.83 to 15.49 ± 3.38 MPa [18].

CF plasma: This type of plasma was studied by the team of Liu (2018). They found bonding values ranging from 19.96 ± 2.91 to 20.12 ± 2.88 MPa [18].

Reactive sandblast treatment: Hatta, et al. [25] in 2011 investigated the bond values of silica-modified 110-µm alumina oxide blasting treatment at 0.28 MPa for 13s (Rocatec Junior). The SBS value was 26.9 ± 7 MPa [25]. The team of Yamamato used in 2016 blasting with 30µm diameter alumina particles for 10s by Rocatec™ Soft and they found 12.4 ± 4.5 MPa [19].

Milling treatment: Milling is used by 2 methods: conventional or Computerized numerical control (CNC). Conventional milling is carried out with milling cutters and a handpiece with a constant speed under water jet [6]. This surface treatment was treated in two studies with a very high heterogeneity regarding the diameter of the milling cutters, the depth of milling and the results. The SBS values ranged from 11.59 ± 5.1 to 28.51 ± 2.21 [6,17]. In contrast, CNC milling is performed with automated and computer-controlled milling machines such as the DWX 50 machine (Roland, Japan), according to a predefined CAD model. This technique can lead to the appearance of cylindrical cavities on the surface of the zirconia. One study evaluated this type of milling and found a bond value of 138 ± 19 MPa. [20]

Coating treatment: To improve the bonding of the materials by compensating the difference in the coefficient of thermal expansion (CTE), an intermediate layer (coating) is deposited between the zirconia and the cosmetic ceramic. Table 3 shows SBS test values after three coating treatments.

Table 2. SBS test values after the laser

Authors |

Type of laser |

SBS (MPa) |

Henriques, et al. [7] |

ND: YAG laser (Neodymium-doped yttrium aluminum garnet) |

65 MPa |

Krmali,et al. [12] |

Laser Er Cr: YSGG (Erbium, Chrome: Yttrium-Scandium- Gallium- Grenat) |

From 14,10 ± 6,48 MPa to 20,54 ± 6,66 MPa. |

Liu, et al. [22]

Abdullah,et al. [23] |

-CO2 laser

- CO2 laser |

From 29,7 ± 6,1 to 31,3 ± 5,7MP

From 30,46 ± 2,03 to 32,08 ± 2,45 MPa. |

Yilmaz,et al. [4] |

Femtosecond laser |

36 ± 3,31 MPa |

Yilmaz,et al. [4] |

Er: YAG laser (Erbium-doped yttrium-aluminum garnet) |

31,02 ± 4,96MPa |

Table 3. SBS test values after coating treatment

Authors |

Nature of coating |

SBS (MPa) |

SILVA- HERZOG RIVERA et al. [15] |

AP40 and 46SP6 glass coating |

Control group :11,95 ± 10,34

Modified group: AP40=15,21 ± 9,9 8

46SP6=13,00 ± 6,2 |

TENG,et al. [24] |

Powder coating |

Control group= 46.12 ± 7.1

Modified group : 47,02 ± 6,4 |

SANTOS, et al. [20] |

Composite Coat |

Control group 89 ± 15

Modified group 100 ± 15 |

Polishing treatment: Polishing is carried out with silicon carbide papers of different grains under cooling [21]. Teng, et al. [29] in 2012, evaluated polishing with silicon carbide paper up to 1200 grains under water cooling. The bond value was 36.66 ± 8.6 MPa [24].

Priming treatment: Priming is a simple surface conditioning method to promote bonding between zirconia and cosmetic ceramics [5]. The study by Spintzyk, et al. [5] evaluated the primer (LUXOR Zirkonoxyd) and found bonding values ranging from 21.2 ± 5.8 to 24.2 ± 5.2 [5]. Korkmaz et al studied 3 types of primers: Clearfil ceramic, Alloy primer, RelyX ceramic, and found the following SBS values: 8.90 ± 3.42; 19.74 ± 4.96 and 10.5 ± 3.01 MPa [17].

Liner treatment: Liners are applied as an intermediate layer between the zirconia substrate and the cosmetic ceramic to mask the framework and increase the wetting properties of the zirconia surface. 8 studies evaluated the effectiveness of liners in improving the zirconia/cosmetic ceramic bond (Table 4).

Table 4. SBS values after liner’s application.

Authors |

Liner |

SBS (MPa) |

YOON,et al., SILVA-HERZOG RIVERA,et al., BITENCOURT, et al., CANULLO,et al.

[2,3 15,27,29] |

IPS emax ZirLiner |

Between 11,39 ± 2,45 and 47,0MPa. |

Kim,et al. [32] |

Amber Ceram Liner |

29,3 ± 3,9MPa |

Lee, et al. [16] |

Zr-Adhesive, Heraeus Kulzer |

Between 26,78 ± 2,25 and 27,84 ± 2,51 MPa. |

Kim,et al. [23] |

Cerabien ZR |

Between 27,87 ± 3,59 MPa.

and 34,4 et 47,0 MPa. |

Heat treatment: This surface treatment can be carried out at different temperatures. It is recommended after sandblasting to eliminate phase transformation. This type of treatment was used in one study: Nishigori, et al. [28] investigated the heat treatment with increasing rate of temperature from 650°c to 1000°c with a rate of 55°c/min and they found bonding values ranging from 28.2 ± 13.7 to 31.2 ± 16.9 MPa.

Application of potassium nitrate: This treatment was performed in only one study. Pre-sintered zirconia blocks were immersed in a 150g potassium nitrate solution for 24 hours before sintering. The bond value was 18.18 ± 1.80 MPa [14].

Combinations of different surface treatments: Table 5 shows SBS values after different combinations of treatments.

Table 5. SBS values after different combinations of treatments.

Authors |

Nature of combinations |

SBS values |

YOON, et al., MOSHARRAF, et al., KIM,et al. [3,6,23] |

Sandblasting and a liner |

between 27.39 ± 6.59 and 47.0 MPa |

Nishigori, et al. [28], Liu, et al. [22] |

Regeneration heat treatment and sandblasting |

from 17.5 ± 8.2 to 29.3 ± 12 MPa. |

Yamamato, et al. [19] |

Glassy coating followed by hydrofluoric acid etching and the application of silane |

16.2 ± 4 MPa |

Spintzyk,et al. [5] |

Sandblasting and a primer |

21.2 ± 5.8 to 24.2 ± 5.2 MPa |

Santos,et al. [20] |

-Milling followed by the application of a composite layer (cosmetic ceramic reinforced with zirconia)

-Sandblasting followed by application of the same layer |

96 ± 11 MPa.

100 ± 15 MPa |

JI,et al. [13] |

Sandblasting and plasma treatment. |

22.46 ± 1.84 MPa. |

Discussion

Our objective was to evaluate the impact of different surface treatments applied on zirconia on the bonding value between the cosmetic ceramic and zirconia. We were confronted with difficulties to synthesize all the results of the research, in particular because of the great heterogeneity of:

-the characteristics of the samples,

-the sizes of the blocks and their shapes,

-the various techniques used to manufacture the blocks: CAD /CAM, milling ....

-and differences in the results of studies evaluating the same surface treatment.

Several types of mechanical tests can be used to find the bonding values between zirconia and cosmetic ceramics. We choose the SBS (shear bond strength) test because it is one of the most widely used methods for testing the interfacial strength of dental materials, although this test has several limitations in relation to real clinical situations and its results should be interpreted with caution [21,29].

Sandblasting is the most evaluated treatment in the studies included in our review, but contradictory results have been observed. Some authors reported an increase in the bond value between zirconia and cosmetic ceramics after sandblasting treatment [2,12,13,22,23]. This finding is consistent with the studies of Nakamura and co-workers, and Aboushelib and co-workers [30,31]. This result is due to the cleaning and roughness improvement with the creation of surface irregularities which improves the mechanical retention, as well as the surface energy and wettability. This also allows a reduction of interfacial fracture rates.

Conversely, other authors have stated that sandblasting does not improve the zirconia/cosmetic ceramic bond and has no effect on the bond strength between the two materials [4,24,28].

Other authors have claimed that sandblasting has decreased the bond value between zirconia and cosmetic ceramics [17,21,32]. This would be due to the surface defects created by sandblasting as well as the possible contamination of zirconia substrates by alumina particles. Due to the small plastic deformation of zirconia, a small amount of alumina particles may remain on the zirconia surface during blasting [21]. This phenomenon can be explained as follows: first, the relation between surface roughness and shear bond strength may not be linear [21]. Secondly, excessive surface roughness may lead to stress concentration that may cause phase change and consequently weaken the interfacial bond between zirconia and the cosmetic ceramic [2,3,32,33]. Furthermore, the phase change results in a mismatch in the coefficient of thermal expansion, the CTE, resulting in residual compressive stress on the cosmetic ceramic and a decrease in the bond strength between the zirconia and the cosmetic ceramic [26,34,35].

The CTE of monoclinic zirconia (7.5 × 10 - 6 / K) is significantly lower than that of tetragonal zirconia (10.8 × 10 - 6 / K) and may weaken the interfacial strength between the zirconia and the cosmetic ceramic [26,36].

3 studies concluded that in order to have a good bond between zirconia and cosmetic ceramics, sandblasting should be done before sintering, otherwise heat treatment is suggested after sandblasting [18,21,28].

Sandblasting was performed, in the studies included in our review by different pressures (from 0.1 to 0.4MPa). Liu, et al. [18] found that sandblasting at 0.4MPa produced the highest shear bond strength, confirming the study of Nakamura, et al. [30].

For Bitencourt, et al. [17], particle diameter affects the zirconia surface. A large alumina particle diameter generated a lower zirconia survival rate despite increasing the roughness [37].

Laser: The Nd YAG laser gives very high bonding values according to Henriques, et al. [7]. High bonding values in this type of laser are due to the micromechanical retention of the cosmetic ceramic at the microcavities created after the laser treatment. On the other hand, for other authors, surface treatment with this laser can damage the zirconia surface: the microcavities created reduce the fracture resistance of zirconia and the heat produced by the laser induces cracks at some microcavities [4,36]. They pointed out that the composition of zirconia has been modified by this type of laser and concluded that Nd:YAG should not be used on zirconia.

Regarding the Er: YAG laser, it has been shown to increase surface roughness [38]. Cavalcanti, et al. [36] in 2009 reported that with high pulse energy parameters (400 and 600 mJ), the Er: YAG laser caused excessive material deterioration such as cracks [39]. In contrast to this, no cracks or black melting points were detected in the group treated with this type of laser in the study by Yilmaz and all who used an energy of 300 mJ [4].

CO2 laser allows good adhesion between zirconia and cosmetic ceramics through the creation of the micro retentions [22,26]. Furthermore, the study by Abdullah, et al. [7] indicates that laser treatment applied 2 or 3 times could increase the surface roughness and provide satisfying shear strength values. The results are in agreement with the studies of Muhammed, et al. [1] and Abdullah, et al.

The femtosecond laser formed regular microcavities on the zirconia surface which provided good adhesion [4]. In addition, it reduced the presence of residual elements [40].

Er, Cr: YSGG: The study of Kirmali, et al. [12] showed that this type of laser increased the bonding value between zirconia and cosmetic ceramics in all groups from 1w to 6w, which confirms the results of the study of Demir, et al. [37].

Plasma: It has been suggested that plasma treatment can improve surface energy, clean the surface by removing organic surface impurities, and produce a super hydrophilic surface [27,40]. The durability of surface properties after plasma treatment is an important consideration in the practical application of this technology in the clinical setting [16]. Plasma treatment can increase the hydrophilicity surface and improve surface energy through soft microretention and functional chemical bonding without changing surface properties, specifically roughness [13,18,41].

Argon plasma is the most common type of plasma used for zirconia surface treatment. This type of plasma treatment increases the polar component by increasing the oxygen elements and reducing the carbon-based contaminations. When the cosmetic ceramic mounting step was delayed for 24 hours after plasma treatment, the water storage condition maintained the cleaning properties as well as the superhydrophilicity of the plasma treatment and did not decrease the value of the zirconia/cosmetic ceramic bond. On the other hand, zirconia surfaces were recontaminated by being left in the air and the bond value decreased. Generally, the different storage conditions after plasma treatment do not affect the bond value between zirconia and cosmetic ceramic [16].

Reactive sandblasting: In the study by Baldissara, et al. [42], sandblasting with silica-coated aluminum oxide is considered an excellent treatment to improve the bond strength between zirconia and cosmetic ceramics, due to the creation of micromechanical retention on the zirconia surface. Silica-coated aluminum oxide particles, 30 microns in size at 2.5 bar pressure were chosen because they caused the least damage [43]. In contrast, the silica deposition in the study by Yamamato, et al. did not optimize bonding, as melting would have occurred due to the high sintering temperature. In addition, it can induce microcracks at the inter-granular level, which can impair the longevity of the restoration [19].

Milling: For some authors, conventional milling and CNC milling increase the bonding value between zirconia and cosmetic ceramics, by increasing the surface roughness [6, 20]. This result is in agreement with the study of Aboushelib, et al. [44]. For other authors, it has no significant effect [17,45]. It has even been reported that milling produces high stresses and unequal distributions of defects and microcracks, with increased surface roughness. These results can all reduce the bond strength and cause a phase change decreasing the reliability of the zirconia [44,45]. The phase change and the reduced bond value could be the result of milling that caused the local development of temperature change. This difference in bond values between studies may be due to a difference in ceramic mounting methods and milling conditions [6,44].

Coating with a glass or composite: For Silva, et al. glass coating increased the bonding value, creating a suitable surface for chemical interactions and increasing the roughness [15,17]. It may be due to the presence of SiO2, Na2O, K2O, CaO, F, MgO, and P2O5 that may allow for better chemical interaction between zirconia and cosmetic ceramics, which explains the difference between the AP40 and 46SP6 coating [46]. The lack of F and MgO, decreased the binding value. On the other hand, Santos, et al. [21], demonstrated that the presence of the ceramic-based composite layer reinforced with 30% of zirconia particles, despite its better mechanical properties, did not contribute to a significant increase in bond strength. This is due to the lack of diffusion of the composite layer onto the zirconia because of the stability of the zirconia at the sintering temperature of the porcelain. This difference in results between the studies would be due to the difference in the nature of the coatings.

The results for the primer were different depending on the type of primer: an increase in the bonding value by the Alloy primer which is a metal primer, and this result is caused by direct bonding between the metal oxides and the MDP monomer [17,47]. In contrast, RelyX ceramic and Clearfil ceramic primers did not improve the bonding value. This is explained by the poor wettability of the silane (RelyX ceramic) on a non-roughened surface [17].

For the Liner the composition of the liner varies depending on the manufacturer, but the main component is SiO2, indicating a composition similar to cosmetic ceramic. The improvement in bond value with liner treatment is observed in some studies [2,23], and this is due to its thermal properties to compensate for variations in the coefficient of thermal expansion between zirconia and cosmetic ceramics as well as its ability to increase the wettability of the zirconia [2,23]. Bitencourt, et al. [27], didn’t find an impact and the team of Kim, et al. [13,15,23], noted a decrease by interfacial breakdown. The application of liner to zirconia surfaces has only been recommended for some cosmetic ceramics and for layering ceramic mounting [3]. This is because it can considerably weaken the bond strength of the zirconia and the veneering ceramic and increase the probability of breakage and delamination, when it’s used with pressed ceramics [23].

Heat treatment was tested in only one study [28] and showed no effect which is in agreement with a study performed by Fisher, et al. [48] who explained that although heat treatment from 650°c to 1000°c makes relaxation of surface compressive stresses, the microcracks did not close at this temperature [33]. In contrast, Denry, et al. reported that heat treatment in the range of 850°c to 1000°c induced the opposite transformation [23].

Application of potassium nitrate increased the bonding value by increasing the mechanical strength of ceramics. Potassium nitrate ions form a compressive layer on the surface of the ceramic and cause a reduction in micro-cracks [14]. In fact, on surfaces containing potassium nitrate, there is an exchange and displacement of ions of different sizes such as sodium and potassium resulting in the formation of a thin surface layer which is resistant to compression.

Combinations of surface treatments: Some studies combined between liner treatment and sandblasting. For Yoon, et al. [3] and Aboushelib, et al. [46], the bonding value is high because the application of liner alone on a smooth surface increases the risk of interfacial fracture and reduces the bond strength between zirconia and cosmetic ceramic [49,50].

Other authors studied the combination of heat treatment and sandblasting. They reported that the heat treatment after sandblasting reversed the crystallographic transformation due to sandblasting [51]. On the other hand, Nishigori, et al. [28] stated that the combination between heat treatment and sandblasting decreases the bonding value between zirconia and cosmetic ceramics compared to single sandblasting: the mechanical retention effect induced by sandblasting and the thermal effect make stresses and defects on the zirconia surface. However, another study found that thermal treatment does not affect the zirconia/cosmetic ceramic bond regardless of the accompanying surface treatment, including sandblasting [59]. According to Ji, et al. [13], the combination between sandblasting and plasma treatment significantly increased the bonding value between zirconia and cosmetic ceramic with an increase in roughness, but it caused a phase transformation on the zirconia surface.

The combination between glassy coating, hydrofluoric acid and silane increases the bonding value according to Yamamato, et al. [19]. This is due to the porosity created by the application of hydrofluoric acid which allows for better mechanical anchoring, as well as the wettability due to the glassy coating [53,54].

The combination of milling or sandblasting and the composite layer (zirconia-reinforced ceramic) increased the bonding value, but with no significant difference compared to blocks without an intermediate layer [20]. Despite its better mechanical properties, the composite layer did not contribute to a significant increase in bond strength between zirconia and the cosmetic ceramic, in contrast to other studies on ceramic-metal bonding that showed a 140% increase in bonding when the composite layer is used between the metal substrate and the cosmetic ceramic, due to a diffusion between the metal oxides found at the 2 surfaces [55].

Conclusion

The majority of surface treatments applied to zirconia increased the bonding value between zirconia and the cosmetic ceramic. Further in vitro studies with standardized protocols and clinical studies taking into consideration occlusal forces, arch area, number of abutments and restoration design are required.

Data availability

The data are conserved in the fixed prosthesis department of the Faculty of Dentistry of Casablanca.

Conflicts of interest

The authors declare that they have no conflicts of interest.

Funding statement

This work was supported by the Faculty of Dentistry of Casablanca.

References

- Muhammed F, Pollington S, Sun X, ABDULLAH AO, Liu Y (2018) Novel coatings on zirconia for improved bonding with veneer ceramics. Coatings 8: 363.

- Yoon HI, Yeo IS, Yi YJ, Kim SH, Lee JB, et al. (2015) Effect of various intermediate ceramic layers on the interfacial stability of zirconia core and veneering ceramics. Acta Odontol Scand 73: 488- 495. [Crossref]

- Yoon HI, Yeo IS, Yi YJ, Kim SH, Lee JB, et al. (2014) Effect of surface treatment and liner material on the adhesion between veneering ceramic and zirconia. J Mech Behav Biomed Mater 40: 369-374. [Crossref]

- Yilmaz-Savas T, Demir N, Ozturk NA, Sukur Kilic H (2016) Effect of Different Surface Treatments on the Bond Strength of Lithium Disilicate Ceramic to the Zirconia Core. Photomed Laser SurgJun 34: 236-243. [Crossref]

- Spintzyk S, Yamaguchi K, Sawada T (2016) Influence of the Conditioning Method for Pre-Sintered Zirconia on the Shear Bond Strength of Bilayered Porcelain/Zirconia. Materials 9: 765

- Mosharraf R, Rismanchian M, Savabi O (2011) Influence of surface modification techniques on shear bond strength between different zirconia cores and veneering ceramics. J Adv Prosthodont 3: 221-228. [Crossref]

- Henriques B, Fabris D, Souza J, Silva FS, Carvalho O, et al. (2018) Bond strength enhancement of zirconia-porcelain interfaces via Nd:YAG laser surface structuring. J Mech Behav Biomed Mater 81: 161-167. [Crossref]

- Sailer I, Feher A, Filser F (2007) Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont 20: 383-388. [Crossref]

- Pjetursson BE, Valente NA, Strasding M, Zwahlen M, Liu S, et al. (2018) A systematic review of the survival and complication rates of zirconia-ceramic and metal-ceramic single crowns. Clin Oral Implants Res 16: 199-214. [Crossref]

- Sailer I, Zembic A, Jung RE, Siegenthaler D, Holderegger C, et al. (2009) Randomized controlled clinical trial of customized zirconia and titanium implant abutments for canine and posterior single-tooth implant reconstructions: preliminary results at 1 year of function. Clin Oral Implants Res 20: 219-225. [Crossref]

- Monaco C, Tucci A, Esposito L, Scotti R (2014) Adhesion mechanisms at the interface between Y-TZP and veneering ceramic with and without modifier. J Dent 42: 1473-1479. [Crossref]

- Kirmali O, Kapdan A, Kustarci A (2016) Veneer ceramic to Y-TZP Bonding: comparison of different surface treatments. J Prosthodont 25: 324-329. [Crossref]

- Ji M, Lee J, Yim E, Park C, Moon BK (2020) Effect of Atmospheric Pressure Plasma Treatment on Shear Bond Strength Between Zirconia and Dental Porcelain Veneer. J Nanosci Nanotechnol 20: 5683-5685. [Crossref]

- Sasany R, Koca M, Ceylan G, Koroglu A (2020) Effect of Potassium Nitrate and Boric Acid on the Bond Strength of Veneering Ceramics to Zirconia. Eur J Prosthodont Restor Dent 28: 182-188. [Crossref]

- Silva‑Herzog Rivera D, Pozos‑Guillen A, Aragón‑Piña A (2020) Glass coatings to enhance the interfacial bond strength between veneering ceramic and zirconia. Odontology 108: 415-423. [Crossref]

- Lee M, Min B, Son J (2016) Influence of different post-plasma treatment storage conditions on the shear bond strength of veneering porcelain to zirconia. Materials (Basel) 9: 43. [Crossref]

- Korkmaz FM, Bagis B, Turgut S, Ates SM, Ayaz EA (2015) Effect of surface treatments on the bond strength of veneering ceramic to zirconia. J Appl Biomater Funct Mater 13: 17-27. [Crossref]

- Liua Y, Hsieha J, Chena Y, Li-Li K, Chii-Shyang H, et al. (2018) Promoting porcelain–zirconia bonding using different atmospheric pressure gas plasmas. Dent Mater 34: 1188-1198. [Crossref]

- Yamamoto LT, Rodrigues VA, Dornelles LS (2016) Low-fusing porcelain glaze application on 3Y-TZP surfaces can enhance zirconia-porcelain adhesion. Braz Dent J 27: 543-547.

- Santos RL, Silva FS, Nascimento RM (2016) Shear bond strength of veneering porcelain to zirconia: effect of surface treatment by CNC-milling and composite layer deposition on zirconia. J Mech Behav Biomed Mater 60: 547-556. [Crossref]

- He M, Zhang Z, Zheng D, Ding N, Liu Y (2014) Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent Mater Journal 33: 778-785. [Crossref]

- Liu D, Matinlinna JP, Tsoi JK, Pow EHN, Miyazaki T, et al. (2013) A new modified laser pretreatment for porcelain zirconia bonding. Dent Mater 29: 559-565. [Crossref]

- Kim HJ, Lim HP, Park YJ, Vang MS (2011) Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent 105: 315-322. [Crossref]

- Teng J, Wang H, Liao Y, Liang X (2012) Evaluation of a conditioning method to improve core-veneer bond strength of zirconia restorations. J Prosthet Dent 6: 380-387. [Crossref]

- Hatta M, Shinya A, Yokoyama D (2011) The effect of surface treatment on bond strength of layering porcelain and hybrid composite bonded to zirconium dioxide ceramics. Journal of Prosthodontic Research 55: 146-153.

- Abdullah AO, Pollington S, Fenik KM (2020) Effect of repeated laser surface treatments on shear bond strength between zirconia and veneering ceramic, J Prosthet Dent 123: 338e1-338e6.

- Bitencourt SB, Dos Santos DM, Da Silva EVF, Barão VAR, Rangel EC, et al. (2018) Characterisation of a new plasma-enhanced film to improve shear bond strength between zirconia and veneering ceramic. Mater Sci Eng C Mater Biol Appl 92: 196-205. [Crossref]

- Nishigori A, Yoshida T, Bottino MC (2014) Influence of zirconia surface treatment on veneering porcelain shear bond strength after cyclic loading. J Prosthet Dent 112: 1392-1398. [Crossref]

- Canullo L, Micarelli C, Bettazzoni L (2014) Shear bond strength of veneering porcelain to zirconia after argon plasma treatment. Int J Prosthodont 27: 137-139. [Crossref]

- Nakamura T, Wakabayashi K, Zaima C, Nishida H, Kinuta S (2009) Tensile bond strength between tooth-colored porcelain and sandblasted zirconia framework. J Prosthodont Res 53: 116-119. [Crossref]

- Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ (2005) Microtensile bond strength of different components of core veneered allceramic restorations. Dent Mater 21: 984-991. [Crossref]

- Kim SH, Park CJ, Cho LR, Huh YH (2018) Evaluation of the ceramic liner bonding efect between zirconia and lithium disilicate. J Prosthet Dent 120: 282-289. [Crossref]

- Fischer J, Grohmann P, Stawarczyk B (2008) Effect of zirconia surface treatments on the shear strength of zirconia/veneering ceramic composites. Dent Mater J 27: 448-454. [Crossref]

- Aboushelib MN, Wang H (2013) Influence of crystal structure on debonding failure of zirconia veneered restorations. Dent Mater 29: 97-102. [Crossref]

- Noda M, Okuda Y, Tsuruki J (2010) Surface damages of zirconia by Nd:YAG dental laser irradiation. Dent Mater J 29: 536-541. [Crossref]

- Cavalcanti AN, Pilecki P, Foxton RM (2009) Evaluation of the surface roughness and morphologic features of Y-TZP ceramics after different surface treatments. Photomed Laser Surg 27: 473-479. [Crossref]

- Demir N, Subasi MG, Ozturk AN (2012) Surface Roughness and Morphologic Changes of Zirconia Following Different Surface Treatments. Photomed Laser Surg 30: 339‑345. [Crossref]

- Abdullah AO, Hui Y, Sun X (2019) Effects of different surface treatments on the shear bond strength of veneering ceramic materials to zirconia. J Adv Prosthodont 11: 65-74. [Crossref]

- Delgado Ruiz RA, Calvo Guirado JL, Moreno P (2011) Femtosecond laser microstructuring of zirconia dental implants. J Biomed Mater Res B Appl Biomater 96: 91-100. [Crossref]

- Baldissara P, Querze M, Monaco C (2013) Efficacy of surface treatments on the bond strength of resin cements to two brands of zirconia ceramic. J Adhes Dent 15: 259-267. [Crossref]

- Souza RO, Valandro LF, Melo RM, Machado JPB, Bottino MA, et al. (2013) Air-particle abrasion on zirconia ceramic using different protocols: effects on biaxial flexural strength after cyclic loading, phase transformation and surface topography. J Mech Behav Biomed Mater 26: 155-163. [Crossref]

- Aboushelib MN, Kleverlaan CJ, Feilzer AJ (2008) Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont 17: 401-408. [Crossref]

- Guazzato M, Albakry M, Ringer SP, Swain MV (2004) Strength, fracture toughness and microstructure of a selection of allceramic materials: Part II: zirconia-based dental ceramics. Dent Mater 20: 449-456. [Crossref]

- Aboushelib M, Kleverlaan C, Feilzer A (2006) Microtensile bond strength of diferent components of core veneered all-ceramic restorationsPart II: zirconia veneering ceramics. Dent Mater 22: 857-863. [Crossref]

- Wang H, Aboushelib MN, Feilzer AJ (2008) Strength influencing variables on CAD/CAM zirconia frameworks. Dent Mater 24: 633-638. [Crossref]

- Denry IL, Peacock JJ, Holloway JA (2010) Effect of heat treatment after accelerated aging on phase transformation in 3Y-TZP. J Biomed Mater Res B Appl Biomater 93: 236-43. [Crossref]

- Coli P, Karlsson S (2004) Precision of a CAD/CAM technique for the production of zirconium dioxide copings. Int J Prosthodont 17: 577-580. [Crossref]

- Fischer J, Stawarczyk B (2007) Compatibility of machined Ce-TZP/Al2O3 nanocomposite and a veneering ceramic. Dent Mater 23: 1500-1505.

- Chan YH, Kim JK, Liu D (2005) Effect of plasma treatment of Au-Ni-Cu bond pads on process windows of Au wire bonding. IEEE Trans Adv Packag 28: 674-684.

- Harding AB, Norling BK, Teixeira EC (2012) The effect of surface treatment of the interfacial surface on fatigue-related microtensile bond strength of milled zirconia to veneering porcelain. J Prosthodont 21: 346-352.

- Aboushelib MN (2011) Evaluation of zirconia/resin bond strength and interface quality using a new technique. J Adhes Dent 13: 255- 260. [Crossref]

- Durand JC, Jacquot B, Salehi H (2012) Confocal Raman microscopic analysis of the zirconia/feldspathic ceramic interface. Dent Mater 28: 661-671.

- Henriques B, Soares D, Silva FS (2011) Optimization of bond strength between gold alloy and porcelain through a composite interlayer obtained by powder metallurgy. Mater Sci Eng A 528: 1415-1420.

- Swain MV (2009) Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater 5: 1668-1677. [Crossref]

- Kanat B, Comlekoglu EM, Comlekoglu DM, Sen BH, Ozcan M, et al. (2014) Effect of various veneering techniques on mechanical strength of computer-controlled zirconia framework designs. J Prosthodont 23: 445-455. [Crossref]